Explore Trends, Innovations, and Achievements at HengZe Steel

What Is Tinplate Coil (ETP / SPTE)? Guide for Buyers & Manufacturers

- Industry News

- March 19, 2023

- 6:32 am

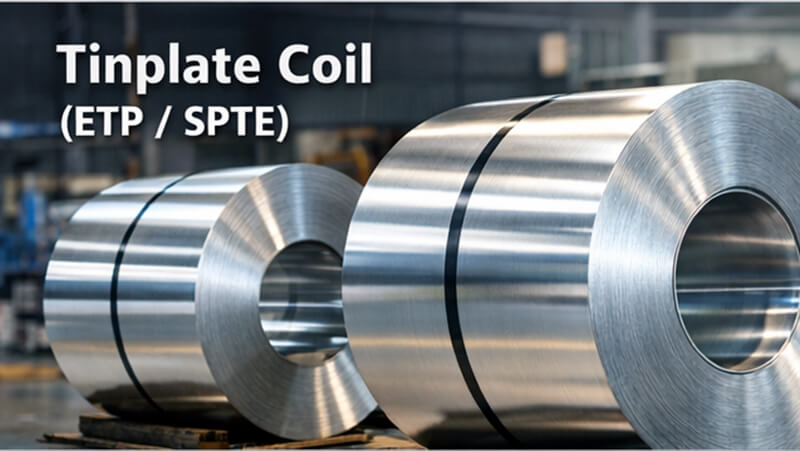

In the global metal packaging and industrial manufacturing sectors, tinplate coil (ETP / SPTE) is a mission-critical material known for its corrosion resistance, formability, and food-safe performance.

As an experienced tinplate coil manufacturer and exporter, Hengze Steel supplies high-quality SPTE / ETP tinplate coils to can makers, packaging factories, and industrial buyers worldwide.

This in-depth guide explains what tinplate coil is, how it is produced, its technical specifications, standards, applications, and how buyers can select the right material for their production needs.

Table of Contents

- 1. What Is Tinplate Coil (ETP / SPTE)?1. What Is Tinplate Coil (ETP / SPTE)?

- 2. ETP vs. SPTE: Terminology Explained2. ETP vs. SPTE: Terminology Explained

- 3. How Tinplate Coil Is Manufactured3. How Tinplate Coil Is Manufactured

- 4. Tinplate Coil Technical Specifications4. Tinplate Coil Technical Specifications

- 5. Surface Finishes & Temper Grades5. Surface Finishes & Temper Grades

- 6. Common Applications of Tinplate Coil6. Common Applications of Tinplate Coil

- 7. Advantages of Tinplate for Packaging & Manufacturing7. Advantages of Tinplate for Packaging & Manufacturing

- 8. International Standards & Quality Control8. International Standards & Quality Control

- 9. Tinplate Coil Buying Guide for Manufacturers9. Tinplate Coil Buying Guide for Manufacturers

- 10. Sustainability & Recycling Performance10. Sustainability & Recycling Performance

- 11. Conclusion: Partner with Hengze Steel11. Conclusion: Partner with Hengze Steel

1. What Is Tinplate Coil (ETP / SPTE)?

Tinplate coil is a cold-rolled low-carbon steel strip electrolytically coated with a thin, uniform layer of tin on both sides. This tin coating significantly enhances corrosion resistance, surface appearance, solderability, and chemical stability.

In international trade and technical documentation, tinplate coil is commonly referred to as:

ETP (Electrolytic Tinplate)

SPTE (Steel Plate Tin Electrolytic)

Both terms describe the same product category, widely used in food packaging tinplate, beverage cans, aerosol containers, and industrial metal packaging.

Primary SEO terms naturally covered here:

tinplate coil for food packaging

SPTE steel coil

ETP tinplate sheet

electrolytic tinplate manufacturer

2. ETP vs. SPTE: Terminology Explained

Although often confusing for new buyers, the distinction is mostly semantic:

ETP (Electrolytic Tinplate)

Refers to the manufacturing process, where tin is deposited via electrolysis.SPTE (Steel Plate Tin Electrolytic)

Refers to the finished product designation, commonly used in export contracts and standards.

👉 In practice, ETP and SPTE are interchangeable terms describing electrolytically tin-coated steel used for packaging and industrial forming.

3. How Tinplate Coil Is Manufactured

High-quality tinplate coil production requires strict process control at every stage:

Low-carbon cold-rolled steel (MR, SPCC, or equivalent) provides:

Excellent formability

Consistent thickness

Mechanical strength for stamping and deep drawing

3.2 Electrolytic Tin Coating

The steel strip passes through an electrolytic bath where:

Tin ions are deposited evenly on both surfaces

Coating weight is precisely controlled (e.g. 2.8/2.8, 5.6/5.6 g/m²)

3.3 Annealing & Surface Treatment

Post-coating annealing improves ductility and eliminates internal stress.

Optional passivation and oiling protect the surface during storage and transport.

Hengze Steel ensures coating uniformity and surface cleanliness suitable for high-speed can-making lines.

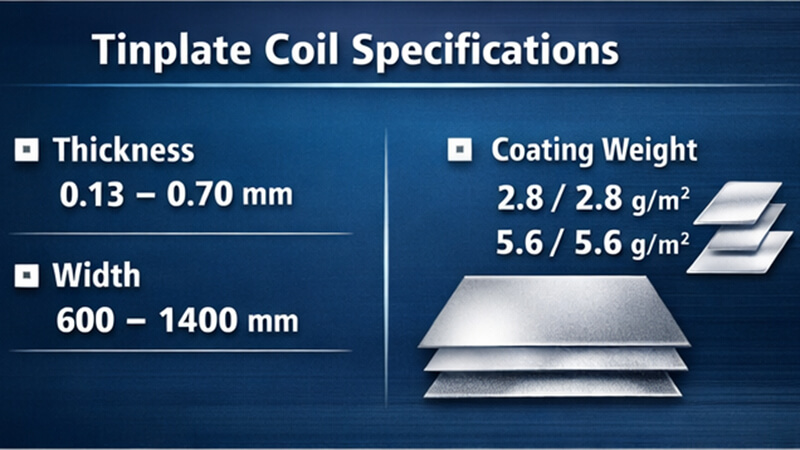

4. Tinplate Coil Technical Specifications

4.1 Thickness & Width Range

Typical production ranges:

Thickness: 0.13 – 0.70 mm

Width: 600 – 1400 mm

(Custom sizes available based on application)

4.2 Tin Coating Weights

Common coating combinations:

1.1 / 1.1 g/m²

2.8 / 2.8 g/m²

5.6 / 5.6 g/m²

Higher coating weights provide enhanced corrosion resistance for aggressive contents.

5. Surface Finishes & Temper Grades

Bright Finish: High gloss, excellent printability

Stone Finish: Reduced reflectivity, stable forming

Matte Finish: Industrial or functional applications

Temper Grades

T1 – T5: Progressive hardness levels for stamping and drawing

DR7 – DR9: Double-reduced grades for lightweight, high-strength cans

Selecting the correct temper is critical for deep drawing tinplate applications.

6. Common Applications of Tinplate Coil

6.1 Food & Beverage Packaging

Food cans (meat, fish, vegetables, fruit)

Beverage and drink cans

Edible oil containers

6.2 Aerosol & Chemical Packaging

Spray cans

Paint and coating containers

Industrial chemical tins

6.3 Electrical & Industrial Components

Electronic housings

Metal caps, lids, closures

Decorative and household containers

7. Advantages of Tinplate for Packaging & Manufacturing

Tinplate coil remains the preferred packaging material due to:

Excellent corrosion resistance

Food-safe and non-toxic surface

Outstanding formability and weldability

Superior printing and branding performance

High strength with lightweight potential

These advantages make SPTE/ETP tinplate ideal for high-volume industrial manufacturing.

8. International Standards & Quality Control

Tinplate coils supplied by Hengze Steel comply with major global standards:

ASTM A623 / A623M

JIS G3303

EN 10202 / EN 10203

GB/T 2520

Each batch can be delivered with:

Mill Test Certificate (MTC)

Coating weight inspection

Surface quality inspection

9. Tinplate Coil Buying Guide for Manufacturers

When sourcing tinplate coil for packaging, buyers should evaluate:

Application requirements (food, chemical, aerosol)

Correct temper and coating weight

Supplier quality control system

Export packaging & logistics experience

Working with a reliable supplier like Hengze Steel reduces production risk and ensures long-term supply stability.

10. Sustainability & Recycling Performance

Tinplate is:

100% recyclable

Easily separated in steel recycling streams

Reusable without performance degradation

This makes tinplate an environmentally responsible choice aligned with global sustainability goals.

11. Conclusion: Partner with Hengze Steel

Understanding tinplate coil specifications, standards, and applications is essential for manufacturers and buyers.

With strong technical expertise, stable supply chains, and strict quality control, Hengze Steel is your reliable partner for:

SPTE / ETP tinplate coils

Food-grade tinplate solutions

Industrial packaging steel materials

Contact Hengze Steel today to discuss your tinplate coil requirements and receive professional technical support.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance