Galvanized Steel Coil and Strip

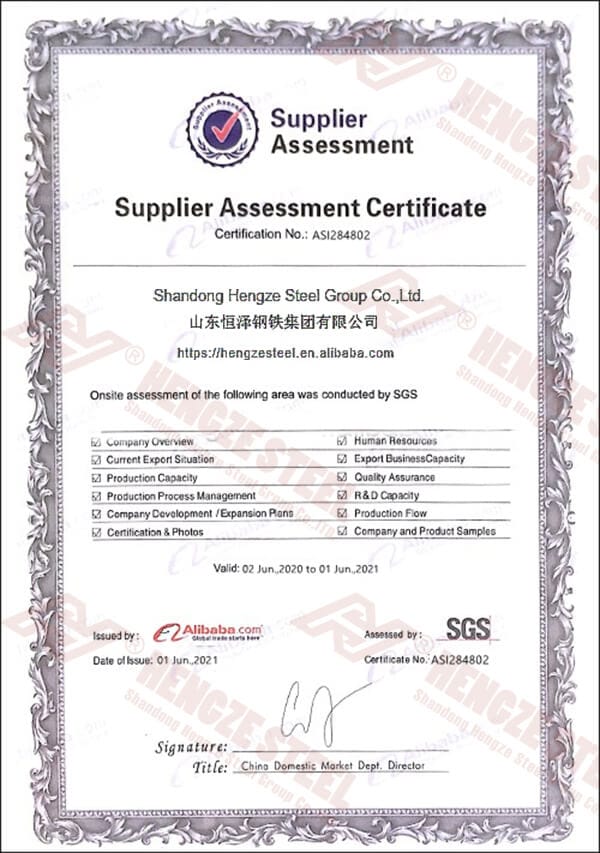

Premium quality galvanized steel coils and strips by Hengze Steel, SGS-certified for superior corrosion resistance and durability.

Galvanized Steel Coil and Strip Manufacturer

Hengze Steel produces high-quality hot-dip galvanized steel coils with superior corrosion resistance, strength, and long-term durability. Using advanced galvanizing lines and strict quality control, we ensure a consistent zinc coating and smooth surface finish.

Our galvanized steel coils are coated by immersing cold-rolled steel into a bath of molten zinc. This process forms a strong bond between the zinc and base steel, providing excellent protection against rust, oxidation, and harsh weather conditions.

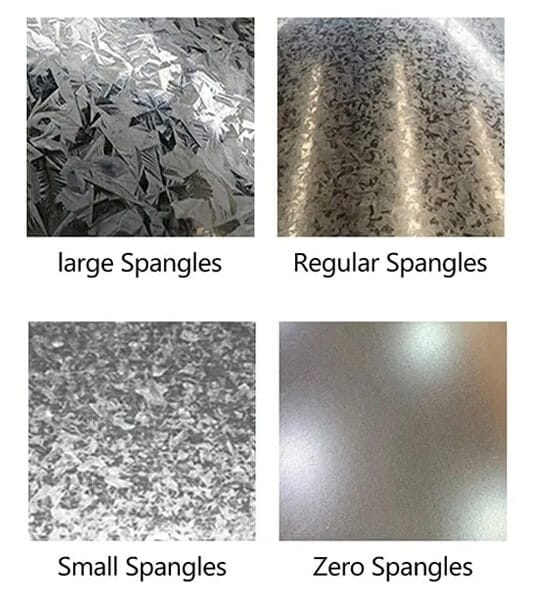

We offer a wide range of zinc coating weights (Z30–Z275), thicknesses, and surface finishes including regular spangle, zero spangle, and minimized spangle. Surface treatments such as chromate, anti-fingerprint, and oiling are also available.

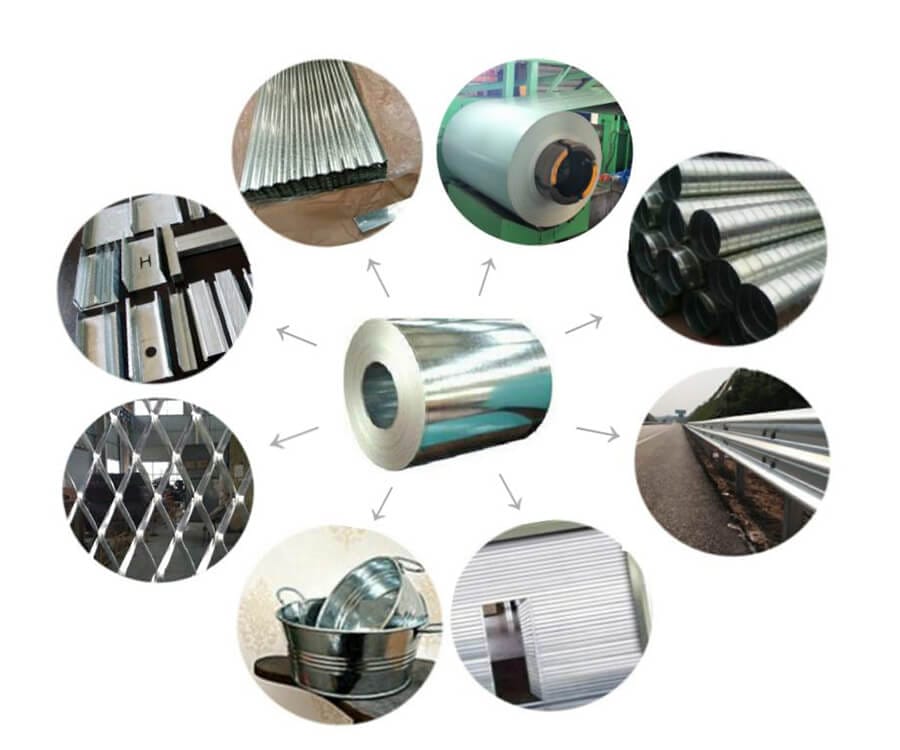

Hengze galvanized coils are widely used in roofing, wall cladding, light steel framing, appliances, automotive parts, and HVAC systems. Custom specifications are available to meet your exact needs.

Choose Hengze Steel for reliable galvanized steel solutions that combine performance, durability, and competitive pricing — trusted by customers worldwide.

Galvanized Coil Specification

| Zinc Coating | 30–275 g/m² |

| Thickness | 0.13–4.0 mm |

| Width | 600–1500 mm |

| Coil ID | 508 mm / 610 mm |

| Coil Weight | 3–8 tons per coil |

| Surface Spangle | Regular, Mini, Zero (for aesthetic or functional requirements) |

| Surface Treatment | Chromated, Oiled, Unoiled, Anti-fingerprint (AFP) coating optional |

| Production Standard | ASTM, JIS, EN, GB (Manufactured to global quality benchmarks) |

Steel Strip Specifications

| Specification | Details |

|---|---|

| Thickness | 0.3–5.0 mm for regular spangle; 0.6–1.8 mm for zero spangle, meeting ASTM A653 standards. |

| Width | 32–860 mm, customizable to fit various processing needs. |

| Coating Weight | 50–275 g/m² zinc coating (G50 to G275), ensuring excellent corrosion protection. |

| Inner Diameter | Standard 508 mm or 610 mm, suitable for most coil handling equipment. |

| Surface Structure | Regular and zero spangle options for aesthetic and functional requirements. |

| Surface Treatment | Environmental and conventional chromate treatments to enhance corrosion resistance. |

Hengze Galvanized Steel Coil – Classification

| Classification Dimension | Available Options | Typical Application / Notes |

|---|---|---|

| Galvanizing Process | Hot-Dip Galvanized (GI / HDG) Electro-Galvanized (EG) Galvannealed (GA) | Determines corrosion resistance, surface quality, and weldability |

| Zinc Coating Grade | G30 / G40 / G60 / G90 Z60 / Z120 / Z180 / Z275 | Higher coating weight provides longer service life |

| Steel Grade (Base Metal) | DX51D / DX52D / DX53D S220GD – S550GD | Controls strength, formability, and load capacity |

| Surface Treatment | Skin-Passed Chromated / Non-Chromated Oiled / Dry | Improves flatness, storage stability, and processing |

| Supply Form & Processing | Coils / Slit Coils / Sheets Custom Slitting & Recoiling | Factory-level customization and delivery flexibility |

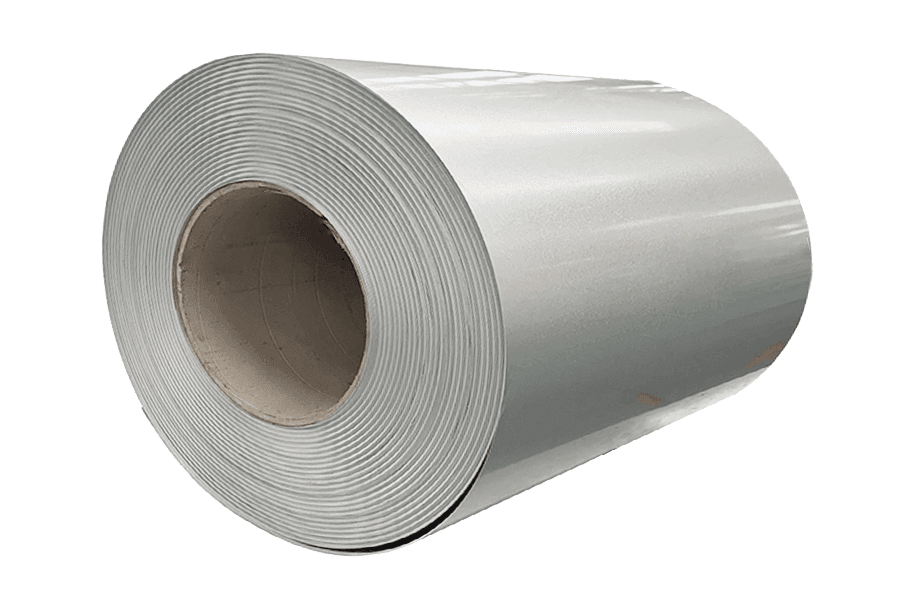

Surface Finishes

Regular Spangle:

The most common galvanized steel coil surface finish, featuring visible zinc crystal patterns. It provides dependable corrosion resistance and is widely used for roofing, structural, and general industrial applications.

Mini Spangle:

A refined surface finish with smaller and more uniform zinc crystals, offering a smoother appearance. Suitable for architectural, decorative, and light industrial uses where appearance matters.

Zero Spangle:

A smooth, uniform surface with no visible zinc patterns. Ideal for prepainted steel (PPGI), appliance panels, and applications requiring excellent paint adhesion and consistent appearance.

Applications and Recommended Specifications

Roofing and Cladding

Our galvanized coils with zinc coating of 275 gsm and thickness from 0.40 mm provide strong weather protection, ideal for roofing and external cladding applications.

Structural Components

For purlins and structural frames, we supply high-strength strips with zinc coating above 275 gsm and thickness from 1.50 mm, ensuring durability and corrosion resistance.

Pipes and Tubes

Galvanized coils with 180 gsm zinc coating and minimum 0.60 mm thickness suit industrial pipes and tubes, offering excellent protection against rust and wear.

Cable Trays and Electrical Systems

We recommend galvanized strips with 275 gsm zinc coating and 1.00 mm thickness, designed for durable cable trays and electrical infrastructure.

Additional Applications

HengZe galvanized steel is also used in automotive, appliances, HVAC ducts, and agricultural machinery, providing reliable corrosion protection and strength.

| Grade | Type | Yield Strength(min, MPa) | Tensile Strength(min, MPa) | Elongation(min, 50 mm, %) |

|---|---|---|---|---|

| CS Type A | Commercial Steel | 140 | 270 | 28 |

| CS Type B | Commercial Steel | 205 | 310 | 26 |

| CS Type C | Commercial Steel | 275 | 340 | 24 |

| FS Type A | Forming Steel | 140 | 270 | 30 |

| FS Type B | Forming Steel | 205 | 310 | 28 |

| DDS | Deep Drawing Steel | 140 | 270 | 34 |

| EDDS | Extra Deep Drawing | 140 | 270 | 36 |

| SS33 | Structural Steel | 230 | 310 | 20 |

| SS37 | Structural Steel | 250 | 340 | 18 |

| SS40 | High Strength Steel | 275 | 380 | 16 |

| SS50 | High Strength Steel | 345 | 450 | 14 |

| HSLAS-F | HSLA Formable Steel | 340–550 | 420–620 | 20–25 |

| Grade | Yield Strength(min, MPa) | Tensile Strength(MPa) | Elongation(min, %) |

|---|---|---|---|

| DX51D | 140 | 270–500 | 22 |

| DX52D | 140 | 270–420 | 26 |

| DX53D | 140 | 260–400 | 28 |

| DX54D | 120 | 260–380 | 30 |

| DX56D | 100 | 260–360 | 36 |

| S220GD | 220 | 270–370 | 22 |

| S250GD | 250 | 330–430 | 20 |

| S280GD | 280 | 360–480 | 18 |

| S320GD | 320 | 390–510 | 16 |

| S350GD | 350 | 420–560 | 14 |

| S550GD | 550 | 570–720 | 10 |

| HX260LAD+Z | 260 | 340–440 | 22 |

| HX340LAD+Z | 340 | 410–510 | 20 |

| Grade | Yield Strength(min, MPa) | Tensile Strength(MPa) | Elongation(min, %) |

|---|---|---|---|

| G250 | 250 | 320–380 | 20 |

| G300 | 300 | 370–430 | 18 |

| G350 | 350 | 420–480 | 16 |

| G450 | 450 | 480–550 | 14 |

| G500 | 500 | 510–650 | 12 |

| G550 | 550 | 550–700 | 8 |

| G250S | 250 | 320–380 | 22 |

| G300S | 300 | 370–430 | 20 |

| G350S | 350 | 420–480 | 18 |

Why Choose Hengze Steel Galvanized Steel Coil?

Hengze Steel manufactures hot-dip galvanized steel coils that fully comply with ASTM A653, EN 10346, and AS 1397 standards. Using advanced galvanizing technology, we ensure a strong zinc-steel bond for long-lasting protection against corrosion, rust, and harsh environments.

Key Specifications

Zinc Coating: Z40–Z275 / G40–G90

Thickness: 0.13 – 1.20 mm

Width: Up to 1500 mm

Spangle: Regular, Zero, Mini, Large

Finish: Chromated, Oiled, Dry

Quality You Can Trust

All products are SGS-certified and customizable in coating, grade, and finish. Hengze delivers dependable galvanized steel solutions tailored to construction, manufacturing, and industrial needs.

Frequently Asked Questions

The service life of galvanized steel coils depends on the zinc coating thickness, environmental conditions, and maintenance. In dry environments, they can last 20–30 years. For coastal or humid areas, a heavier zinc coating (e.g., Z275) is recommended for better corrosion resistance.

Prices vary based on steel base prices, zinc ingot costs, coil thickness, coating grade, and market supply-demand trends. For accurate pricing, it’s best to request a custom quote from the supplier.

Yes. Galvanized coils are often lightly oiled to prevent oxidation and rust during storage and transportation. Customers can also choose dry or oiled surfaces based on specific processing requirements.

Galvanized steel can be cut using laser or plasma cutting and welded using proper methods. However, special ventilation and fume extraction systems should be used due to zinc fumes generated during welding.

Common standards include ASTM A653, JIS G3302, and EN 10346. Popular grades such as SGCC, DX51D, and S280GD offer different mechanical properties for forming, strength, and corrosion resistance.

Get a Quote Today

At HengZe Steel, we supply high-quality Galvanized Steel Coils with excellent corrosion resistance and long-term durability, suitable for construction, roofing, and industrial applications.

Our team provides reliable support, including product specifications, grade selection, technical guidance, and competitive pricing, ensuring you choose the right galvanized steel coil for your project.

For detailed technical information, please refer to our “Galvanized Steel Coil Guide: Grades, Selection & Applications”

📩 Contact us: sales@risso-chem.com