Explore Trends, Innovations, and Achievements at HengZe Steel

How to Choose the Right Steel Coil for Your Project

- Industry News

- December 9, 2025

- 1:55 am

Selecting the right steel coil is a critical engineering and procurement decision that directly influences product performance, structural integrity, corrosion resistance, cost efficiency, and long-term reliability. For industries ranging from construction to automotive, choosing the proper coil ensures that projects are durable, efficient, and compliant with international standards.

As a leading steel coil manufacturer and exporter, Hengze Steel provides a wide range of hot-rolled, cold-rolled, galvanized, pre-painted, and stainless steel coils, tailored for diverse industrial applications. With multiple steel grades, coatings, thicknesses, and surface treatments, selecting the right steel coil requires a systematic, technical, and application-driven approach.

This guide offers a comprehensive, professional, and ptimized framework to help engineers, procurement managers, and project owners make informed decisions when selecting steel coils.

Table of Contents

- 1. Understanding Steel Coils: Definition and Types1. Understanding Steel Coils: Definition and Types

- 2. Define Your Project Requirements First2. Define Your Project Requirements First

- 3. Choose the Right Steel Type for Your Application3. Choose the Right Steel Type for Your Application

- 4. Select the Appropriate Steel Grade4. Select the Appropriate Steel Grade

- 5. Determine Thickness, Width, and Coil Weight5. Determine Thickness, Width, and Coil Weight

- 6. Consider Surface Treatments and Coatings6. Consider Surface Treatments and Coatings

- 7. Evaluate Mechanical Properties and Fabrication Performance7. Evaluate Mechanical Properties and Fabrication Performance

- 8. Assess Corrosion Resistance and Environmental Factors8. Assess Corrosion Resistance and Environmental Factors

- 9. Standards, Certifications, and Regulatory Compliance9. Standards, Certifications, and Regulatory Compliance

- 10. Processing Compatibility and Fabrication Considerations10. Processing Compatibility and Fabrication Considerations

- 11. Quality Control, Testing, and Documentation11. Quality Control, Testing, and Documentation

- 12. Cost Optimization and Supply Chain Management12. Cost Optimization and Supply Chain Management

- 13. Common Mistakes to Avoid13. Common Mistakes to Avoid

- 14. Final Checklist for Choosing the Right Steel Coil14. Final Checklist for Choosing the Right Steel Coil

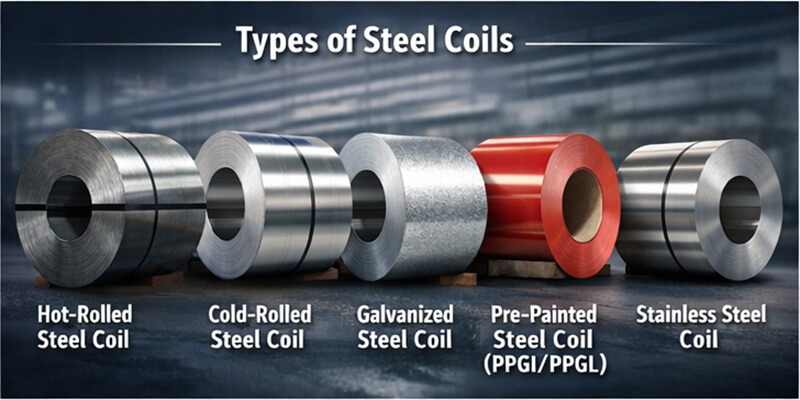

1. Understanding Steel Coils: Definition and Types

A steel coil is a continuous strip of steel, either hot-rolled or cold-rolled, wound into a coil for efficient transportation, storage, and processing. Steel coils are widely used in:

Construction (beams, roofing, wall panels)

Manufacturing (appliances, machinery)

Automotive (body panels, structural parts)

Energy & Infrastructure (pipelines, HVAC systems)

Common types of steel coils include:

Hot Rolled Steel Coil (HRC): High-temperature rolled steel, cost-effective, rougher surface, ideal for structural frameworks.

Cold Rolled Steel Coil (CRC): Rolled at room temperature, smooth surface, tight tolerances, higher strength, ideal for precision components.

Galvanized Steel Coil (GI): Zinc-coated for corrosion protection, widely used in roofing, wall panels, and HVAC systems.

Galvalume / Aluzinc Steel Coil (GL): Aluminum-zinc coated for superior corrosion and heat resistance.

Prepainted Steel Coil (PPGI / PPGL): Factory-coated for decorative and functional applications.

Stainless Steel Coil: Corrosion-resistant, durable, suitable for chemical, food, and high-end applications.

2. Define Your Project Requirements First

Before selecting a steel coil, define your project specifications:

End-use application: Structural, decorative, load-bearing, forming, or high-precision.

Service environment: Indoor, outdoor, coastal, industrial, high humidity, or chemical exposure.

Expected lifespan: Short-term vs. long-term durability requirements.

Fabrication methods: Stamping, bending, welding, roll forming.

Regulatory compliance: ASTM, EN, JIS, GB, or ISO standards.

A requirements-driven selection prevents over-specification, underperformance, or excessive cost.

3. Choose the Right Steel Type for Your Application

| Steel Type | Key Features | Ideal Applications |

|---|---|---|

| Hot-Rolled Steel Coil (HRC) | High-temperature rolling, ductile, cost-effective, rough surface | Structural components, pipes, frames |

| Cold-Rolled Steel Coil (CRC) | Smooth surface, tight tolerances, higher strength | Automotive, appliances, precision parts |

| Galvanized Steel Coil (GI) | Zinc coating, corrosion-resistant | Roofing, wall panels, HVAC systems |

| Galvalume / Aluzinc (GL) | Aluminum-zinc coating, superior corrosion | Long-life construction, outdoor structures |

| Prepainted Steel Coil (PPGI/PPGL) | Painted, decorative, UV-resistant | Building facades, appliances, cladding |

| Stainless Steel Coil | Excellent corrosion resistance | Chemical industry, food, medical, outdoor equipment |

4. Select the Appropriate Steel Grade

Steel grade determines strength, ductility, and chemical composition, affecting fabrication performance and lifecycle durability. Common grading systems:

ASTM: A36, A572, A653

EN: DX51D, S235, S350GD

JIS: SGCC, SPCC

GB: Q235, Q345

Key considerations:

Yield strength and tensile strength

Carbon content and alloying elements

Formability and weldability

Compatibility with fabrication processes

Pro Tip: Matching steel grade to load-bearing and environmental conditions is critical for long-term performance.

5. Determine Thickness, Width, and Coil Weight

Thickness: Thin gauges improve formability; thicker gauges enhance load capacity.

Width: Standard widths reduce waste; custom widths optimize production line efficiency.

Weight: Must align with handling equipment capacity and logistics constraints.

Correct dimensions ensure material efficiency, cost savings, and safe handling.

6. Consider Surface Treatments and Coatings

Surface treatment significantly affects durability, corrosion resistance, and aesthetics. Common options:

Zinc coating (GI): Basic corrosion protection

Al-Zn coating (GL): Enhanced corrosion and thermal resistance

Paint systems (polyester, SMP, HDP, PVDF): UV resistance, aesthetics, long-term protection

Critical factors: Coating type, thickness (e.g., Z275, AZ150), and uniformity.

7. Evaluate Mechanical Properties and Fabrication Performance

Yield strength & tensile strength: Determines structural capacity

Elongation & ductility: Key for forming, stamping, or bending

Hardness: Influences wear resistance and machinability

A consistent mechanical profile prevents cracking, springback, or tool damage.

8. Assess Corrosion Resistance and Environmental Factors

Environmental exposure drives material selection:

Coastal areas: Higher coating mass or stainless steel

Industrial zones: Chemical and pollutant resistance

High temperatures: Thermal stability and coating adherence

Proper selection reduces maintenance costs and extends service life.

9. Standards, Certifications, and Regulatory Compliance

Ensure compliance with:

ISO 9001 / ISO 14001

Mill Test Certificates (MTC / EN 10204 3.1)

RoHS / REACH (where applicable)

Compliance guarantees traceability, consistent quality, and regulatory acceptance.

10. Processing Compatibility and Fabrication Considerations

Confirm steel coil suitability for:

Welding (carbon equivalent control)

Bending radius requirements

Roll forming, stamping, or punching

Surface finishing or painting

Mismatched material can cause cracking, coating failure, or part deformation.

11. Quality Control, Testing, and Documentation

Key quality checks include:

Chemical composition analysis

Mechanical property testing

Coating thickness and adhesion measurement

Surface inspection

Partner with suppliers who provide comprehensive documentation and inspection reports.

12. Cost Optimization and Supply Chain Management

Beyond price, consider:

Material efficiency & yield

Processing and fabrication costs

Maintenance and replacement expenses

Lead time, availability, and logistics

A holistic cost analysis ensures long-term project success and ROI.

13. Common Mistakes to Avoid

Choosing steel based solely on price

Ignoring environmental exposure and corrosion risk

Overlooking fabrication compatibility

Selecting incorrect standards or grades

Avoiding these mistakes reduces project delays, rework, and lifecycle costs.

14. Final Checklist for Choosing the Right Steel Coil

Before finalizing your selection, confirm:

Application type and service environment

Steel type and grade

Thickness, width, and coil weight

Surface treatment and coating specifications

Compliance with standards and certifications

Supplier reliability, quality documentation, and support

Conclusion

Selecting the right steel coil is a strategic material decision that balances performance, durability, compliance, and cost efficiency. By systematically evaluating project requirements, steel type, grade, dimensions, surface treatment, mechanical properties, and standards, project stakeholders can minimize risk, optimize lifecycle value, and ensure long-term project success.

Partnering with a trusted manufacturer like Hengze Steel ensures consistent quality, adherence to international standards, and reliable supply for construction, manufacturing, automotive, and infrastructure projects worldwide.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance