Explore Trends, Innovations, and Achievements at HengZe Steel

How to Choose the Right PPGL Steel Coil

- Industry News

- September 3, 2023

- 2:29 am

This article provides a comprehensive guide on how to choose the right PPGL steel coil — including its composition, AZ coating grades, paint systems (PE, SMP, PVDF), quality inspection, and application-specific recommendations. Learn how to identify the best PPGL coil for roofing, wall cladding, and appliance use with professional insights from Hengze Steel, a trusted global manufacturer of prepainted galvalume coils.

Table of Contents

- 1. Introduction: What Is PPGL?1. Introduction: What Is PPGL?

- 2. PPGL vs. PPGI — Key Differences2. PPGL vs. PPGI — Key Differences

- 3. Structure of PPGL Coil3. Structure of PPGL Coil

- 4. Technical Specifications and Standards4. Technical Specifications and Standards

- 5. Paint Systems and Performance Comparison5. Paint Systems and Performance Comparison

- 6. Application-Based Selection Guide6. Application-Based Selection Guide

- 7. Quality Inspection and Acceptance Criteria7. Quality Inspection and Acceptance Criteria

- 8. Procurement and Storage Recommendations8. Procurement and Storage Recommendations

- 9. Common Defects and Root Causes9. Common Defects and Root Causes

- 10. Quick Selection Checklist (for Buyers)10. Quick Selection Checklist (for Buyers)

- 11. Conclusion and Recommendations11. Conclusion and Recommendations

1. Introduction: What Is PPGL?

PPGL (Pre-Painted Galvalume Steel) is short for Prepainted Aluminum-Zinc Alloy Coated Steel Coil. It consists of a steel base coated with an aluminum-zinc alloy (typically 55% Al, 43.5% Zn, and 1.5% Si), followed by chemical treatment, primer coating, topcoat painting, and baking.

This multilayer protection gives PPGL coils excellent corrosion resistance, heat reflectivity, and long-lasting aesthetic appeal — making them ideal for roofing, wall panels, home appliances, and industrial applications.

Hengze Steel, as a leading PPGL coil manufacturer in China, supplies a wide range of prepainted galvalume products with superior coating uniformity, precise color control, and international standard compliance (ASTM, EN, GB/T).

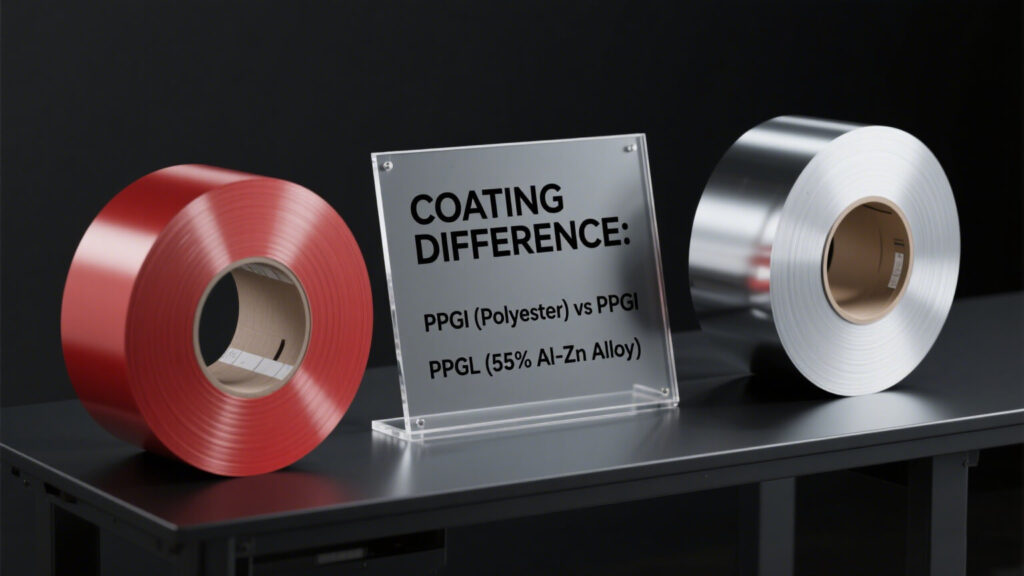

2. PPGL vs. PPGI — Key Differences

| Feature | PPGL (Prepainted Galvalume) | PPGI (Prepainted Galvanized) |

|---|---|---|

| Coating Type | Aluminum-Zinc (Al-Zn) Alloy | Zinc (Zn) |

| Typical Composition | 55% Al, 43.5% Zn, 1.5% Si | 100% Zn |

| Corrosion Resistance | Excellent (Up to 3× that of PPGI) | Moderate |

| Heat Resistance | High | Medium |

| Recommended Usage | Coastal, Industrial, or High-Temperature Areas | Inland or General Applications |

The aluminum-zinc alloy layer of PPGL offers both barrier protection (from aluminum) and sacrificial protection (from zinc), providing longer service life than traditional PPGI.

3. Structure of PPGL Coil

Base Metal: Cold-rolled steel such as DX51D, G300, or G550.

Tip: Choose higher strength grades (e.g., G550) for structural roofing, and softer grades (e.g., DX51D) for forming applications.

Al-Zn Coating (AZ Coating): Common grades include AZ50, AZ100, AZ150.

AZ150 (150 g/m² total coating) is a preferred choice for outdoor use due to superior corrosion resistance.

Surface Treatment: Includes chemical passivation, anti-fingerprint coating, or light oiling to enhance adhesion and oxidation resistance.

Paint System: Consists of primer and topcoat layers — the main factor influencing color, gloss, and weather resistance.

Hengze Steel uses advanced continuous coating lines to ensure uniform thickness, consistent color tone, and superior adhesion across the coil surface.

4. Technical Specifications and Standards

| Parameter | Typical Range / Description |

|---|---|

| Thickness | 0.12 – 1.0 mm |

| Width | 600 – 1250 mm |

| Al-Zn Coating Weight | AZ30 – AZ275 (AZ150 = standard outdoor grade) |

| Steel Grade | G300, G550, or DX51D |

| Paint Thickness | 20/5 µm (PE) to 25/12 µm (PVDF) |

| Standards | ASTM A792 / EN 10346 / GB/T 14978 |

Before ordering, always specify the coating type (AZ), steel grade, paint system, and required standards in the purchase contract.

5. Paint Systems and Performance Comparison

| Coating Type | Features | Typical Application |

|---|---|---|

| PE (Polyester) | Economical, flexible, wide color range; moderate UV resistance | Indoor panels, interior decoration |

| SMP (Silicone Modified Polyester) | Better gloss retention and UV resistance than PE | Wall panels, mid-range roofing |

| PVDF (Polyvinylidene Fluoride) | Excellent color retention, UV, and corrosion resistance | Coastal, industrial, high-end façades |

For long-term outdoor exposure (over 15–20 years), PVDF is the best option. Hengze Steel provides full paint system customization and RAL color matching to meet architectural design requirements.

6. Application-Based Selection Guide

| Application | Recommended Configuration |

|---|---|

| Roofing / Outdoor Panels | PPGL AZ150 + PVDF / SMP; thickness 0.45–0.6 mm |

| Exterior Wall / Facade Panels | PPGL + PVDF coating; verify batch color consistency |

| Home Appliances / Interior Panels | PPGL or PPGI + PE coating; smooth surface finish |

| Cold Forming / Structural Profiles | DX51D base for flexibility; ensure T-bend ≤ 3T |

Hengze Steel offers both coil and sheet forms tailored for roofing, sandwich panels, cold-formed sections, and decorative profiles — ensuring consistent performance and quality across applications.

7. Quality Inspection and Acceptance Criteria

When receiving goods, check:

Mill Test Certificate (MTC) — includes coating weight, paint system, and mechanical properties.

Visual Inspection — no scratches, blisters, or edge rust.

Color & Gloss Consistency — ΔE ≤ 1.5 (recommended tolerance).

Laboratory Tests:

Salt Spray (ASTM B117)

T-Bend / Erichsen cupping

Adhesion (Cross-hatch test)

Impact resistance

Hengze Steel performs 100% inline inspection, salt-spray testing, and gloss evaluation before shipment to ensure long-term durability and color consistency.

8. Procurement and Storage Recommendations

Clearly specify in contract: steel grade, coating weight (AZ), paint system, color code (RAL), and acceptance criteria.

Transportation: Keep coils dry, upright, and well-packed with waterproof wrapping.

Storage: Store indoors on wooden pallets, away from acid fumes and moisture.

Shelf life: Use “first-in, first-out” (FIFO) to avoid surface oxidation or edge corrosion.

9. Common Defects and Root Causes

| Defect | Possible Cause | Prevention |

|---|---|---|

| Peeling / Delamination | Inadequate surface treatment or contamination | Ensure proper chemical pretreatment |

| Rusting at Edges | Low coating weight or moisture exposure | Choose AZ150+ and improve packaging |

| Color Fading / Chalking | Low-grade paint under UV exposure | Use PVDF for long-term weathering |

| Scratches / Abrasion | Improper handling or decoiling | Use protective films and careful transport |

10. Quick Selection Checklist (for Buyers)

| Item | Specification |

|---|---|

| Product | PPGL Color Coated Steel Coil |

| Brand | Hengze Steel |

| Base Metal | DX51D / G550 (specify) |

| Al-Zn Coating | AZ150 (or as required) |

| Thickness | ___ mm |

| Width | ___ mm |

| Paint System | PVDF 25/12 µm or SMP 20/10 µm |

| Color Code | RAL ___ |

| Surface Treatment | Passivation / Anti-fingerprint / Oiled |

| Packing | Standard export seaworthy |

| Inspection Standard | ASTM / EN / GB as per contract |

11. Conclusion and Recommendations

Choose by environment:

Long-term outdoor / coastal → PPGL AZ150 + PVDF

General architecture → PPGL + SMP

Indoor / appliances → PPGL or PPGI + PE

Ensure all technical parameters (AZ coating, paint type, steel grade) are clearly stated in contracts.

Verify coating performance (salt spray, adhesion, T-bend) with supplier reports before shipment.

Partner with reliable manufacturers like Hengze Steel, who provide strict quality control, stable supply, and customized color-matching for architectural and industrial use.

Frequently Asked Questions about PPGL Steel

A: It indicates a total aluminum-zinc coating mass of 150 g/m² on both sides, offering superior corrosion resistance for outdoor use.

A: Not completely. While PPGL offers excellent corrosion resistance at a much lower cost, stainless steel is still recommended for food processing or highly corrosive environments.

For coastal and marine environments, AZ100–AZ150 g/m² with PVDF top coat is recommended.

Yes, manufacturers can supply RAL or custom colors with different gloss or embossed finishes based on project needs.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance