Explore Trends, Innovations, and Achievements at HengZe Steel

How to Choose the Right Corrugated Roofing Sheet Manufacturer

- Industry News

- December 23, 2022

- 1:54 am

A Professional Buyer’s Guide for Construction & Industrial Projects

Choosing the right corrugated roofing sheet manufacturer is a critical decision that directly affects the durability, safety, and long-term cost of any construction project. Whether for industrial buildings, warehouses, agricultural structures, or commercial facilities, corrugated roofing sheets remain one of the most widely used roofing solutions worldwide due to their strength, lightweight design, and cost efficiency.

However, not all manufacturers offer the same level of quality, consistency, or service. This guide provides a professional, in-depth framework to help buyers, contractors, and project owners select a reliable corrugated metal roofing supplier with confidence.

At the beginning of your sourcing journey, working with an experienced manufacturer such as Hengze Steel can significantly reduce procurement risks, especially for international projects requiring stable quality and standardized production.

Table of Contents

- 1️⃣ Define Your Technical Requirements Before Selecting a Manufacturer1️⃣ Define Your Technical Requirements Before Selecting a Manufacturer

- 2️⃣ Evaluate Manufacturing Quality and International Standards2️⃣ Evaluate Manufacturing Quality and International Standards

- 3️⃣ Consider Corrosion Resistance and Climate Adaptability3️⃣ Consider Corrosion Resistance and Climate Adaptability

- 4️⃣ Assess Production Capacity and Delivery Reliability4️⃣ Assess Production Capacity and Delivery Reliability

- 5️⃣ Customization Capabilities and Technical Support5️⃣ Customization Capabilities and Technical Support

- 6️⃣ Price Transparency and Overall Cost Performance6️⃣ Price Transparency and Overall Cost Performance

- 7️⃣ Supplier Reputation and Project Experience7️⃣ Supplier Reputation and Project Experience

- 8️⃣ Practical Checklist for Choosing the Right Manufacturer8️⃣ Practical Checklist for Choosing the Right Manufacturer

- Conclusion: Choose Long-Term Reliability Over Short-Term SavingsConclusion: Choose Long-Term Reliability Over Short-Term Savings

1️⃣ Define Your Technical Requirements Before Selecting a Manufacturer

Before comparing suppliers, it is essential to clearly define your project-specific roofing requirements. This step ensures accurate quotations and prevents costly mismatches later.

Key specifications to confirm include:

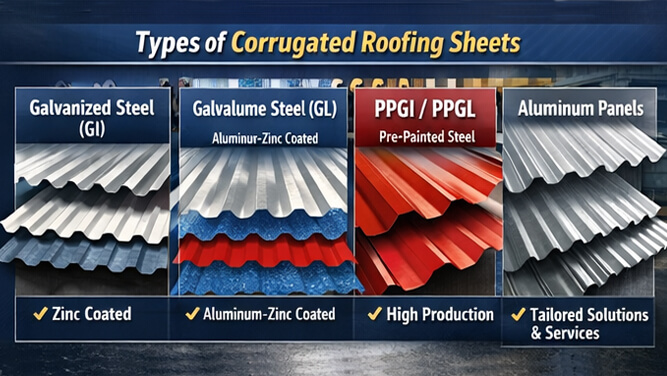

Base material: galvanized steel (GI), galvalume / Al-Zn steel (GL), pre-painted galvanized steel (PPGI), pre-painted galvalume steel (PPGL), aluminum, or stainless steel

Sheet thickness and load capacity: directly impacts wind resistance, structural strength, and service life

Profile type: traditional corrugated, trapezoidal, or customized profiles for drainage efficiency and aesthetics

Sheet length and effective width: optimized for roof slope and installation efficiency

Coating system: PE, SMP, HDP, or PVDF coatings, depending on environmental exposure

Clearly defined parameters make it easier to evaluate whether a corrugated roofing sheet manufacturer has the technical capability to meet your project needs.

2️⃣ Evaluate Manufacturing Quality and International Standards

A professional corrugated roofing sheet supplier must operate under strict quality control systems. This is non-negotiable for long-term roofing performance.

Look for manufacturers that comply with recognized international standards such as:

ASTM (American standards)

EN (European standards)

JIS (Japanese standards)

ISO quality management systems

High-quality manufacturers should also provide:

Mill Test Certificates (MTC)

Coating thickness and zinc/aluminum coating weight reports

Salt spray and corrosion resistance test data

These documents confirm that galvanized or pre-painted corrugated roofing sheets meet design and durability expectations.

3️⃣ Consider Corrosion Resistance and Climate Adaptability

Environmental conditions play a decisive role in material selection. A reliable corrugated metal roofing manufacturer should be able to recommend suitable materials for different climates.

Coastal or high-humidity areas: galvalume or PVDF-coated roofing sheets offer superior corrosion resistance

Industrial or polluted zones: higher-grade coatings resist chemical and acid exposure

High-UV regions: HDP or PVDF coatings minimize color fading and coating degradation

Manufacturers with strong technical expertise will guide buyers toward the most cost-effective solution without compromising service life.

4️⃣ Assess Production Capacity and Delivery Reliability

Production capability is especially important for large-scale or time-sensitive projects.

Key factors to evaluate include:

Monthly or annual output capacity

Number and automation level of roll-forming lines

Lead time consistency for bulk orders

Experience in export packaging and international logistics

In the middle of supplier evaluation, many global buyers prefer established exporters like Hengze Steel, as stable production capacity and predictable delivery schedules are essential for overseas construction projects.

5️⃣ Customization Capabilities and Technical Support

Not all projects use standard roofing profiles. A competitive corrugated roofing sheet manufacturer should offer:

Custom sheet lengths and profiles

Multiple color and coating options

Matching accessories such as ridge caps and flashing

Technical drawings and installation guidance

Value-added services reduce installation errors and improve overall project efficiency.

6️⃣ Price Transparency and Overall Cost Performance

Price should never be evaluated in isolation. Instead of choosing the lowest quotation, buyers should consider total lifecycle cost.

Compare suppliers based on:

Material grade and coating performance

Expected service life under real conditions

Packaging quality and damage prevention

Warranty terms and after-sales support

A slightly higher unit price often results in lower maintenance costs and longer roof lifespan.

7️⃣ Supplier Reputation and Project Experience

Reputation reflects long-term reliability. When selecting a corrugated roofing sheet supplier, consider:

Export experience and target markets

Client feedback and repeat customers

Participation in industrial, commercial, or infrastructure projects

Willingness to support third-party inspections or factory audits

Experienced manufacturers demonstrate consistency across multiple projects and regions.

8️⃣ Practical Checklist for Choosing the Right Manufacturer

To simplify decision-making, verify whether the supplier meets the following criteria:

Clear compliance with international standards

Stable production and delivery capacity

Climate-appropriate material recommendations

Customization and technical support

Transparent pricing and documentation

Proven export and project experience

Conclusion: Choose Long-Term Reliability Over Short-Term Savings

Selecting the right corrugated roofing sheet manufacturer is a strategic decision, not just a purchasing task. High-quality materials, proper coatings, and reliable production directly influence roof performance, safety, and maintenance costs over decades.

By working with a professional supplier such as Hengze Steel, buyers can secure consistent quality, international compliance, and dependable delivery—key factors for successful construction and industrial roofing projects.

If you need further assistance with material selection, coating comparison, or supplier evaluation for your specific market, feel free to reach out for expert guidance.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance