Explore Trends, Innovations, and Achievements at HengZe Steel

Galvanized Steel Coil Guide: Grades, Selection & Applications

- Industry News

- November 22, 2022

- 2:17 am

Galvanized Steel Coil is one of the most widely used materials in construction, industrial manufacturing, home appliances, and infrastructure projects. Selecting the right grade and zinc coating is crucial to ensure long-term durability, corrosion resistance, and performance. Many engineers and global buyers often ask:

Which galvanized steel coil is most suitable for roofing, wall panels, or industrial structures?

Should I choose DX51D or DX52D for deep drawing and stamping applications?

Can S350GD replace DX51D for structural applications without affecting formability?

What zinc coating weight (Z100, Z180, Z275) ensures optimal corrosion protection in different environments?

This comprehensive guide covers grade selection, mechanical properties, zinc coating types, surface treatments, and international standards, offering practical advice for engineers, procurement teams, and project managers.

Hengze Steel, a global supplier of high-quality galvanized steel coil, provides technical guidance to help customers select the right material, optimize costs, and meet project specifications.

Table of Contents

- 1️⃣ What Is Galvanized Steel Coil?1️⃣ What Is Galvanized Steel Coil?

- 2️⃣ Manufacturing Process & Performance Mechanism2️⃣ Manufacturing Process & Performance Mechanism

- 3️⃣ Global Standards & Grade Systems3️⃣ Global Standards & Grade Systems

- 4️⃣ EN 10346 Grade System Explained (DX vs S Series)4️⃣ EN 10346 Grade System Explained (DX vs S Series)

- 5️⃣ Zinc Coatings & Surface Treatments5️⃣ Zinc Coatings & Surface Treatments

- 6️⃣ Mechanical Properties & Formability Logic6️⃣ Mechanical Properties & Formability Logic

- 7️⃣ Application-Based Selection Strategy7️⃣ Application-Based Selection Strategy

- 8️⃣ Common Technical Misunderstandings8️⃣ Common Technical Misunderstandings

- 9️⃣ FAQs: Galvanized Steel Coil9️⃣ FAQs: Galvanized Steel Coil

- 🔟 Final Selection Checklist for Procurement🔟 Final Selection Checklist for Procurement

- 11. Conclusion: Partner with Hengze Steel11. Conclusion: Partner with Hengze Steel

1️⃣ What Is Galvanized Steel Coil?

Galvanized Steel Coil is a steel strip or coil coated with zinc or zinc alloy through a continuous hot-dip galvanizing process, forming a metallurgical bond that enhances corrosion resistance and long-term durability.

It is extensively used for roofing sheets, wall cladding, structural components, appliances, and industrial machinery, where protection against moisture, industrial pollution, and chemical exposure is critical.

Typical Specifications:

Thickness: 0.12 – 6.0 mm

Width: 600 – 1500 mm

Zinc coating: Z60 – Z275 g/m², or AZ/ZM coatings for marine, industrial, and highly corrosive environments

This makes galvanized steel coil ideal for projects that require high-strength coated steel with long service life, such as commercial buildings, warehouses, bridges, and outdoor equipment.

2️⃣ Manufacturing Process & Performance Mechanism

Galvanized steel coils are produced on a Continuous Hot-Dip Galvanizing Line (CGL):

Cleaning & pickling — removes oil, rust, and surface impurities.

Annealing — optimizes steel grain structure for better formability.

Hot-dip immersion — ensures strong metallurgical bonding of zinc.

Air knife coating control — precise regulation of zinc layer thickness.

Cooling, skin pass & surface treatment — enhances flatness, appearance, and paint adhesion.

The performance of galvanized steel coil depends on both the base steel grade (DX or S series) and the type and thickness of zinc coating, which together determine corrosion resistance, formability, and structural integrity.

By understanding these interactions, engineers can select the right steel coil for deep drawing, stamping, or load-bearing applications, avoiding over-specification or underperformance.

3️⃣ Global Standards & Grade Systems

| Region | Standard | Key Specification |

|---|---|---|

| Europe | EN | EN 10346 |

| USA | ASTM | ASTM A653 / A792 |

| Japan | JIS | JIS G3302 |

| China | GB/T | GB/T 2518 |

Different standards define mechanical properties, coating weight, and surface finish differently. For example, DX51D in EN 10346 may have slightly different formability and elongation compared to ASTM A653 Commercial Steel. Always verify datasheets before selecting a galvanized steel coil for critical projects.

Proper understanding of these standards is especially important when sourcing steel coils for construction, industrial applications, or export projects, ensuring compliance with local building codes and engineering requirements.

4️⃣ EN 10346 Grade System Explained (DX vs S Series)

4.1 DX Series — Forming & Deep Drawing Grades

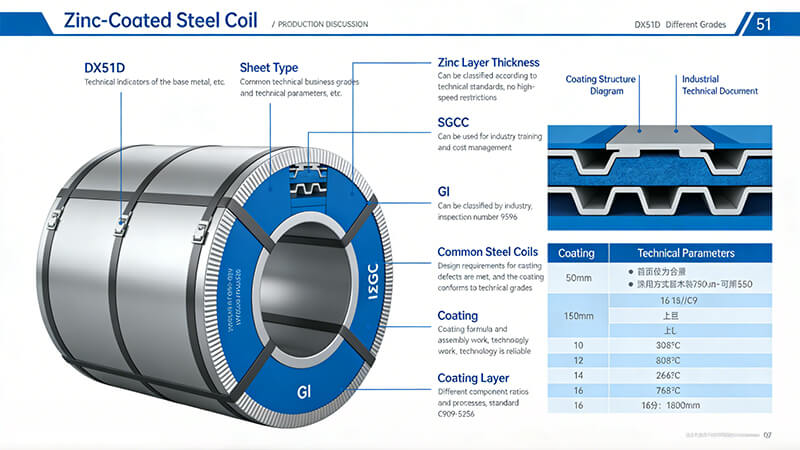

The DX series represents low-carbon steel optimized for forming and drawing applications. These grades are suitable for roofing sheets, wall cladding, appliance panels, and automotive body parts.

| Grade | Formability | Typical Applications |

|---|---|---|

| DX51D | General forming | Roofing, cladding, light-duty profiles |

| DX52D | Medium deep drawing | Cold-formed profiles, housings, panels |

| DX53D | Deep drawing | Appliance panels, automotive body parts |

| DX54D–DX57D | Extra-deep drawing | Complex stamping, automotive components |

Insight: Higher DX numbers correspond to higher elongation, making them ideal for deep drawing and stamping applications, while strength remains adequate for most non-structural uses.

4.2 S Series — Structural Galvanized Steel Grades

The S series is designed for load-bearing structural applications, classified by minimum yield strength.

| Grade | Yield Strength ≥ | Typical Use |

|---|---|---|

| S220GD | 220 MPa | Light structural framing |

| S280GD | 280 MPa | Purlins, steel framing |

| S350GD | 350 MPa | Heavy-duty structural beams, columns |

| S450GD / S550GD | ≥450 MPa | Large-span structures, bridges, industrial facilities |

Selection logic:

Load-bearing structures → S series

Formability & deep drawing → DX series

With proper grade selection, Hengze Steel helps clients optimize both cost and performance for international projects, ensuring compliance with standards like EN 10346, ASTM, and JIS.

5️⃣ Zinc Coatings & Surface Treatments

Zinc coating type and thickness are critical for long-term corrosion protection.

| Coating | Composition | Recommended Environment |

|---|---|---|

| Z (GI) | Pure zinc | General outdoor use |

| ZF | Zinc-iron | Painting base |

| AZ | 55% Al-Zn | High weather resistance |

| ZM | Zn-Mg-Al | Marine and industrial environments |

Surface treatments may include chromated or Cr-free passivation, anti-fingerprint coatings, or skin-pass treatment to ensure flatness and paint adhesion. Selecting the right coating is essential for applications such as roofing, outdoor industrial equipment, and marine structures, where environmental corrosion can significantly impact service life.

6️⃣ Mechanical Properties & Formability Logic

| Grade | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|

| DX51D | ≥140 MPa | 270–500 MPa | ≥22% |

| DX52D | ≥140 MPa | 270–420 MPa | ≥26% |

| S350GD | ≥350 MPa | ≥420 MPa | — |

| S550GD | ≥550 MPa | ≥560 MPa | — |

Forming applications → elongation is critical

Structural applications → yield strength dominates

Zinc coating affects corrosion resistance, not mechanical performance

By understanding these relationships, engineers can select the optimal galvanized steel coil for roofing sheets, appliance panels, automotive parts, or industrial structures.

7️⃣ Application-Based Selection Strategy

Construction & Roofing

DX51D with Z100 / Z180 / Z275 coating

Ideal for residential and commercial roofing, wall cladding, and lightweight structural panels

Cold Forming & Stamping

DX52D / DX53D

High-elongation galvanized steel coils suitable for appliance panels, HVAC components, and automotive stamping

Structural Components

S280GD / S350GD

For bridges, warehouse frames, and heavy-duty purlins

AZ or ZM coatings recommended for highly corrosive or coastal environments

8️⃣ Common Technical Misunderstandings

❌ Thicker zinc coating ≠ higher steel strength

❌ DX grades are not interchangeable with S series structural grades

❌ Similar grade names across EN, ASTM, or JIS ≠ identical performance

❌ Over-specification increases cost without functional benefits

9️⃣ FAQs: Galvanized Steel Coil

Q1: What is Galvanized Steel Coil used for?

Galvanized steel coil is widely used for roofing, cladding, structural frames, appliances, HVAC systems, and industrial machinery due to its corrosion resistance, formability, and long service life.

Q2: Which grade is best for deep drawing?

DX53D or higher is recommended, providing higher elongation for stamping and forming.

Q3: How to select the right zinc coating weight?

Z275 is suitable for outdoor applications; AZ or ZM coatings are preferred for marine, industrial, and high-corrosion environments.

Q4: Can structural grade S350GD replace DX51D?

No. While S350GD provides higher strength, it has limited formability and is unsuitable for deep drawing or stamping applications.

Q5: Are EN 10346 and ASTM A653 galvanized steel coils interchangeable?

Only if mechanical properties, coating thickness, and surface treatments are verified. Always consult datasheets for cross-standard selection.

🔟 Final Selection Checklist for Procurement

Application type (forming, stamping, load-bearing)

Applicable standard (EN / ASTM / JIS / GB)

Zinc coating type and thickness for durability

Processing method (bending, stamping, welding)

Cost-performance optimization for long-term use

Hengze Steel provides expert guidance, datasheets, and customized galvanized steel coil solutions for construction, industrial, and export projects.

Conclusion

Selecting the right Galvanized Steel Coil is about matching steel grade, coating type, and application requirements, not simply choosing the strongest steel. With proper understanding of DX vs S series, coating options, and international standards, engineers and procurement professionals can optimize performance, cost, and durability.

Hengze Steel offers premium galvanized steel coils, technical support, and international-standard solutions for global projects in construction, manufacturing, and industrial sectors.

About Hengze Steel

Hengze Steel specializes in Galvanized Steel Coil, Galvalume Steel, and PPGI/PPGL, supplying EN, ASTM, JIS, and GB standards worldwide.

📩 Contact Hengze Steel for samples, specifications, or consultation for your next project.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance