Explore Trends, Innovations, and Achievements at HengZe Steel

Galvalume Steel Coils Thickness Guide: AZ50, AZ100, AZ150

- Industry News

- July 15, 2023

- 6:54 am

This article delivers a comprehensive and technically accurate guide to Galvalume steel coil thickness, clearly explaining the differences between AZ50, AZ100, and AZ150 coating grades. It covers Galvalume composition, coating weight systems (oz/ft² vs g/m²), thickness conversion logic, corrosion resistance performance, and real-world application scenarios. By aligning ASTM A792 and EN 10346 standards with practical selection guidance, the content helps engineers, contractors, and procurement professionals choose the optimal Galvalume specification for roofing, cladding, and industrial projects. The guide also highlights how reliable manufacturers such as Hengze Steel ensure consistent coating quality, long service life, and cost-effective performance across global markets.

Table of Contents

- 1. Introduction — Why Galvalume Coating Thickness Matters1. Introduction — Why Galvalume Coating Thickness Matters

- 2. What Is Galvalume Steel? Composition & Key Advantages2. What Is Galvalume Steel? Composition & Key Advantages

- 3. Understanding AZ Coating Codes (Imperial vs Metric Systems)3. Understanding AZ Coating Codes (Imperial vs Metric Systems)

- 4. AZ50 vs AZ100 vs AZ150 — Thickness, Coating Weight & Performance4. AZ50 vs AZ100 vs AZ150 — Thickness, Coating Weight & Performance

- 5. Corrosion Resistance & Durability Expectations5. Corrosion Resistance & Durability Expectations

- 6. Application-Based Selection Guide6. Application-Based Selection Guide

- 7. Fabrication, Forming, Welding & Paintability Considerations7. Fabrication, Forming, Welding & Paintability Considerations

- 8. Relevant Standards & Technical Specifications8. Relevant Standards & Technical Specifications

- 9. Cost vs Service Life: How to Optimize Material Selection9. Cost vs Service Life: How to Optimize Material Selection

- 10. Frequently Asked Questions (FAQ)10. Frequently Asked Questions (FAQ)

- 11. Conclusion & Quick Reference Summary11. Conclusion & Quick Reference Summary

1. Introduction — Why Galvalume Coating Thickness Matters

When specifying Galvalume steel coils, coating thickness is one of the most critical technical parameters. It directly affects corrosion resistance, service life, maintenance cost, and long-term structural reliability.

In practical applications—roofing systems, wall cladding, industrial enclosures—selecting the correct AZ coating grade ensures the steel performs as expected throughout its design life.

Manufacturers like Hengze Steel focus heavily on precise coating weight control, ensuring that AZ50, AZ100, and AZ150 products meet or exceed international standards such as ASTM A792 and EN 10346.

2. What Is Galvalume Steel? Composition & Key Advantages

Galvalume steel (also known as Aluzinc or AZ-coated steel) is carbon steel coated with an aluminum-zinc alloy, typically composed of:

≈55% Aluminum – provides barrier protection and oxidation resistance

≈43.5% Zinc – offers sacrificial (cathodic) corrosion protection

≈1.5% Silicon – improves coating adhesion and processing stability

Key advantages over traditional galvanized steel:

2–4× longer corrosion resistance in many environments

Superior heat reflectivity and thermal stability

Improved performance at cut edges and scratches

Excellent substrate for coil coating and painting systems

These characteristics make Galvalume coils from reliable suppliers such as Hengze Steel widely used in architectural, industrial, and infrastructure applications.

3. Understanding AZ Coating Codes (Imperial vs Metric Systems)

Galvalume coating weights are expressed using two commonly accepted systems:

Imperial System (ASTM A792)

AZ50 = 0.50 oz/ft² (combined coating on both sides)

AZ55 = 0.55 oz/ft² (combined)

This system is widely used in North America.

Metric System (EN / International Markets)

AZ150 = 150 g/m² (combined both sides)

AZ120, AZ180, etc., follow the same logic

Conversion Reference

1 oz/ft² ≈ 305 g/m²

AZ50 (0.50 oz/ft²) ≈ 150 g/m²

👉 This is why AZ50 (imperial) is often commercially equivalent to AZ150 (metric). Always confirm whether the quoted coating weight is combined both sides or per side.

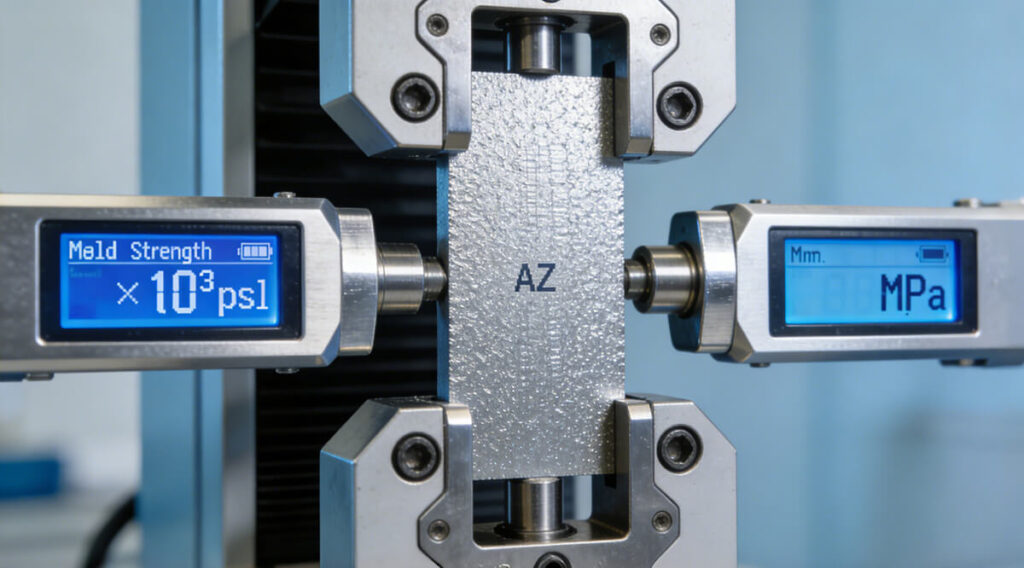

4. AZ50 vs AZ100 vs AZ150 — Thickness, Coating Weight & Performance

| AZ Grade | Coating Weight (Combined) | Approx. Micron Thickness* | Typical Applications |

|---|---|---|---|

| AZ50 | ~150 g/m² | ~5–11 μm per side | Painted roofing, wall panels |

| AZ100 | ~300 g/m² | ~10–22 μm per side | Industrial buildings, warehouses |

| AZ150 | ~450 g/m² | ~15–30 μm per side | Coastal, chemical, heavy-duty roofing |

*Actual micron thickness varies by supplier and coating process. Reputable mills such as Hengze Steel provide mill test certificates (MTC) detailing exact coating mass and thickness.

5. Corrosion Resistance & Durability Expectations

Higher AZ coating weights significantly enhance corrosion resistance:

AZ50 / AZ55: Suitable for mild to moderate environments, especially when painted

AZ100: Improved protection in industrial or semi-coastal regions

AZ150: Designed for aggressive environments with salt spray, humidity, or pollutants

Laboratory salt-spray tests (ASTM B117) consistently show longer time-to-red-rust performance for higher AZ grades, though real-world performance depends on installation, design, and maintenance.

6. Application-Based Selection Guide

Recommended AZ grades by application:

Residential & commercial roofing (painted): AZ50 / AZ55

Industrial roofs & wall cladding: AZ100

Coastal, agricultural, chemical plants: AZ150

Unpainted or exposed structures: AZ100–AZ150 preferred

For export projects and long-term infrastructure, many buyers choose Hengze Steel Galvalume coils due to stable coating consistency and customizable specifications.

7. Fabrication, Forming, Welding & Paintability Considerations

Forming: Galvalume offers excellent formability; tighter bend radii require higher coating quality

Welding: Special attention is required due to aluminum content; follow supplier welding guidelines

Painting: Galvalume is an excellent substrate for PVDF, SMP, and PE coatings, particularly in AZ50/AZ55 grades

Proper processing preserves coating integrity and extends service life.

8. Relevant Standards & Technical Specifications

When sourcing Galvalume steel coils, ensure compliance with:

ASTM A792 / A792M – Al-Zn coated steel (AZ grades)

EN 10346 – Continuously hot-dip coated steel products

JIS G3321 – Japanese standard for Al-Zn coated steel

Always request:

Coating weight (g/m² or oz/ft²)

Yield & tensile strength

Coating thickness per side

Surface finish and spangle

Warranty terms (especially for painted coils)

9. Cost vs Service Life: How to Optimize Material Selection

While higher AZ grades carry a higher upfront cost, they often reduce:

Maintenance frequency

Replacement cycles

Long-term ownership cost

For projects with long design life or difficult access, AZ100 or AZ150 Galvalume coils provide better lifecycle value than lower coatings.

10. Frequently Asked Questions (FAQ)

Q: Is AZ50 the same as AZ150?

A: Technically, yes—AZ50 (0.50 oz/ft²) ≈ AZ150 (150 g/m²). The difference lies in imperial vs metric notation.

Q: Which AZ grade is best for coastal environments?

A: AZ150 is strongly recommended for coastal and high-salt environments.

Q: Does Galvalume steel rust?

A: Over time, all steel can corrode, but Galvalume significantly delays red rust compared to standard galvanized steel.

11. Conclusion & Quick Reference Summary

Choosing the correct Galvalume coating thickness—AZ50, AZ100, or AZ150—is essential for ensuring durability, performance, and cost efficiency.

Understanding coating weight systems, application environments, and international standards helps engineers, buyers, and contractors make informed decisions.

For consistent quality, precise coating control, and export-ready specifications, manufacturers such as Hengze Steel remain a trusted source of Galvalume steel coils worldwide.

⭐ Why Hengze Steel Is a Recommended Galvanized Steel Coil Supplier

Final Checklist

If you are sourcing Galvalume steel coils from China, Hengze Steel is a strong and reliable choice because:

✔ 25+ years manufacturing GI, GL, PPGI, PPGL coils for global markets

✔ Advanced hot-dip galvanizing lines with strict QC

✔ Flexible MOQ & fast delivery

✔ Zinc coatings from Z100–Z450

✔ International standards: ASTM, EN, JIS, GB

✔ Full traceability + professional export documentation

✔ Competitive pricing & stable quality trusted by large importers

For buyers needing roofing materials, construction steel, automotive-grade GI, or high-coating Z275+ coils, Hengze Steel consistently delivers high-performance, export-ready solutions.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance