Explore Trends, Innovations, and Achievements at HengZe Steel

Corrugated Roofing Sheets Price Guide: Cost by Material & Thickness

- Industry News

- October 24, 2022

- 2:08 am

This comprehensive corrugated roofing sheets price guide by Hengze Steel provides detailed insights into cost variations based on material type, sheet thickness, coating, and regional factors. Covering galvanized steel, galvalume, pre-painted steel (PPGI/PPGL), aluminum, and polycarbonate options, the guide helps buyers, contractors, and project owners make informed decisions that balance budget, performance, and durability. Learn practical tips for optimizing total roofing costs, comparing supplier pricing, and selecting the right material for industrial, commercial, or residential roofing projects.

Table of Contents

- 1️⃣ What Are Corrugated Roofing Sheets?1️⃣ What Are Corrugated Roofing Sheets?

- 2️⃣ Key Factors Affecting Corrugated Roofing Sheets Price2️⃣ Key Factors Affecting Corrugated Roofing Sheets Price

- 3️⃣ Corrugated Roofing Sheets Cost by Material Type3️⃣ Corrugated Roofing Sheets Cost by Material Type

- 4️⃣ Corrugated Roofing Sheets Price by Thickness4️⃣ Corrugated Roofing Sheets Price by Thickness

- 5️⃣ Regional Market Price Comparison5️⃣ Regional Market Price Comparison

- 6️⃣ Practical Tips to Control Roofing Procurement Cost6️⃣ Practical Tips to Control Roofing Procurement Cost

- 7️⃣ Conclusion: Balancing Cost and Performance7️⃣ Conclusion: Balancing Cost and Performance

1️⃣ What Are Corrugated Roofing Sheets?

Corrugated roofing sheets are profiled metal or plastic panels formed into wave or trapezoidal patterns to enhance load-bearing capacity, rigidity, and drainage efficiency while maintaining lightweight and ease of installation.

They are widely applied in industrial buildings, warehouses, agricultural facilities, commercial roofs, and residential projects, where durability, cost efficiency, and installation speed are critical. Depending on project requirements, materials include:

Galvanized steel (GI)

Galvalume / Aluzinc steel (AZ)

Pre-painted steel sheets (PPGI / PPGL)

Aluminum sheets

Polycarbonate or plastic roofing sheets

For global buyers seeking high-performance corrugated roofing sheets, Hengze Steel offers a complete range of options, backed by industry-standard quality and professional consultation.

Understanding how corrugated roofing sheets price per square meter varies by material, thickness, and coating is essential for accurate budgeting and long-term cost management.

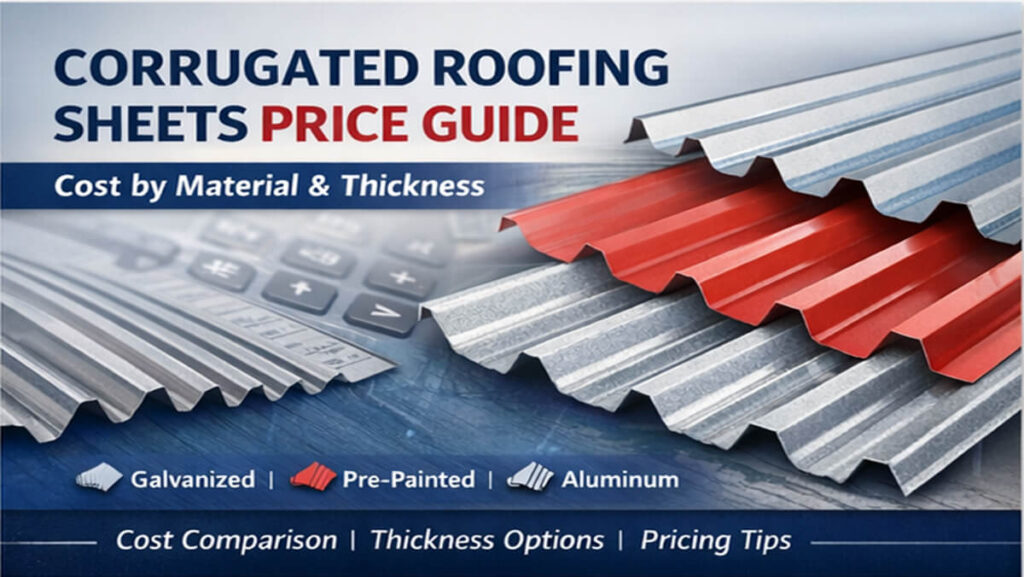

2️⃣ Key Factors Affecting Corrugated Roofing Sheets Price

The final price of corrugated roofing sheets depends on multiple technical and market variables.

Material Type

Material is the primary factor influencing cost.

Galvanized steel: Lowest cost, moderate corrosion resistance

Galvalume / AZ: Superior corrosion protection, higher price

Pre-painted sheets (PPGI / PPGL): Added visual appeal and coating durability

Aluminum: Lightweight and highly corrosion-resistant, premium cost

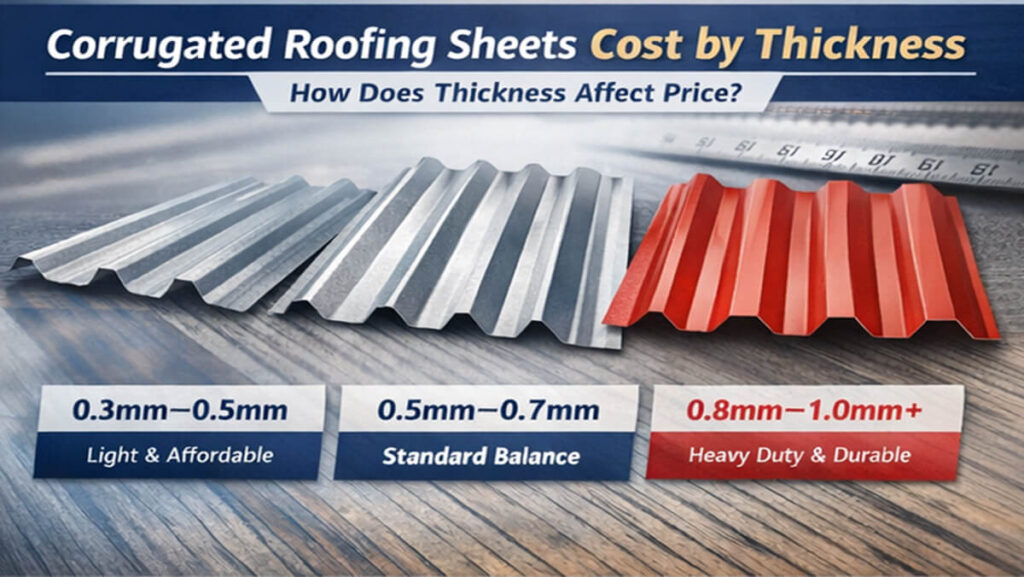

Sheet Thickness

Thickness directly affects steel consumption, strength, and wind/snow load performance. Buyers frequently compare corrugated roofing sheets cost by thickness, as even small changes can impact the budget significantly.

Coating & Surface Treatment

Protective coatings such as PE, SMP, or PVDF enhance weather resistance and color retention but increase manufacturing cost. Selecting an appropriate coating can reduce long-term maintenance.

Profile Design & Dimensions

Effective cover width, corrugation depth, and custom sheet length affect unit cost. Non-standard sizes or special profiles generally carry higher prices.

Market & Supply Chain Factors

Raw material price fluctuations, freight costs, order quantity, and regional supply-demand balance impact Hengze Steel’s pricing and other supplier quotations.

3️⃣ Corrugated Roofing Sheets Cost by Material Type

Galvanized Steel Corrugated Sheets

Widely used in industrial and agricultural roofing

Cost-effective solution

Typical reference: USD 350–650 / MT (FOB Asia)

Galvalume / Aluzinc Corrugated Sheets

Aluminum-zinc coating for superior corrosion resistance

Preferred for humid or coastal areas

Reference: USD 500–800 / MT

Pre-Painted Corrugated Sheets (PPGI / PPGL)

Combines structural strength with color coating

Popular for warehouses and commercial roofs

Reference: USD 550–950 / MT

Aluminum Corrugated Sheets

Lightweight, rust-free, premium durability

Ideal for coastal or chemical environments

Reference: USD 1,300–3,300 / MT

Polycarbonate / Plastic Sheets

Used for daylighting or translucent roofing applications

Cost varies with thickness, UV protection, and impact resistance

Hengze Steel supplies all these material options with consistent quality standards, helping clients select the optimal roofing solution for budget and performance.

4️⃣ Corrugated Roofing Sheets Price by Thickness

0.3–0.5 mm (Light Gauge)

Lowest cost, suitable for temporary buildings or sheds

Limited structural and wind resistance

0.5–0.7 mm (Medium Gauge)

Widely used for residential and commercial roofs

Balance between strength, durability, and price

0.7–1.2 mm+ (Heavy Gauge)

Industrial facilities, long-span roofs, or high wind/snow zones

Higher material cost justified by improved structural safety

Rule of thumb: Every 0.1 mm increase in thickness significantly raises corrugated metal roofing sheets price per sqm, even for the same material type.

5️⃣ Regional Market Price Comparison

Pricing varies by region due to local manufacturing, labor cost, and transport:

Asia & Africa: Competitive pricing, local manufacturing capacity

Middle East: Preference for corrosion-resistant options (Galvalume or Aluminum)

Europe & North America: Higher material and labor costs, stricter standards

Hengze Steel offers both FOB and delivered pricing, helping clients understand total project cost including logistics, import duties, and inland transportation.

6️⃣ Practical Tips to Control Roofing Procurement Cost

Choose thickness based on actual load requirements

Select material according to environmental exposure to avoid premature corrosion

Compare multiple supplier quotes, considering coating quality and warranty

Bulk purchasing to reduce unit cost

Consider total system cost, including fasteners, flashing, and installation labor

A slightly higher material cost can reduce maintenance and replacement expenses, improving lifecycle value.

7️⃣ Conclusion: Balancing Cost and Performance

The best corrugated roofing solution balances cost, performance, and environmental requirements:

✅ Budget-limited, low-corrosion environment → Galvanized steel, medium thickness

✅ Long-term commercial or residential roofs → PPGI / Galvalume sheets

✅ High corrosion or coastal zones → Aluminum or Galvalume heavy-gauge sheets

By understanding corrugated roofing sheets cost by material and thickness, buyers and contractors can make informed decisions that optimize both initial investment and long-term value.

Hengze Steel supports clients worldwide with high-quality roofing materials, professional guidance, and competitive pricing, ensuring optimal performance across all project types.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance