Explore Trends, Innovations, and Achievements at HengZe Steel

What Materials Are Used for Corrugated Roofing Sheets?

- Industry News

- November 13, 2025

- 5:59 am

Corrugated roofing sheets are essential in construction, industrial, and residential projects. Choosing the right material—galvanized steel (GI), aluminum-zinc (Galvalume/Al-Zn), aluminum, fiber-cement, or polycarbonate—affects durability, corrosion resistance, weight, and structural performance. Zinc coatings provide sacrificial protection, while Al-Zn coatings combine barrier and galvanic protection for extended service life. Pre-painted options (PPGI/PPGL) with PVDF or SMP topcoats enhance aesthetics, UV resistance, and longevity. Non-metal alternatives like fiber-cement and polycarbonate serve specific needs, including fire resistance, translucency, and lightweight design. Factors such as environmental exposure, roof span, load, thickness, and lifecycle cost guide selection. Hengze Steel offers high-quality corrugated sheets with precise coating, consistent thickness, and international standard compliance, ensuring long-term performance and reliability.

Table of Contents

- Overview: Why Material Choice MattersOverview: Why Material Choice Matters

- 2. Main Material Categories for Corrugated Sheets2. Main Material Categories for Corrugated Sheets

- 3. Non-Metal Corrugated Sheets3. Non-Metal Corrugated Sheets

- 4. Material Selection Criteria4. Material Selection Criteria

- 5. Durability, Coating Systems & Service Life5. Durability, Coating Systems & Service Life

- 6. Weight, Structural & Installation Considerations6. Weight, Structural & Installation Considerations

- 7. Standard Specification & Procurement Checklist7. Standard Specification & Procurement Checklist

- 8. Frequently Asked Questions8. Frequently Asked Questions

- 9. Conclusion Choosing the Right Supplier9. Conclusion Choosing the Right Supplier

1. Overview: Why Material Choice Matters

The material of corrugated roofing sheets defines not just the roof’s strength and durability, but also its resistance to corrosion, wind, UV exposure, and overall service life.

Choosing the correct substrate and coating can extend a roof’s lifetime by up to three times, reduce maintenance costs, and improve sustainability. For over a decade, Hengze Steel has specialized in producing high-quality corrugated roofing materials that meet ASTM, EN, and JIS standards—ensuring both performance reliability and cost efficiency.

2. Main Material Categories for Corrugated Sheets

2.1 Galvanized Steel (GI)

Definition: Steel substrate coated with a layer of zinc through the hot-dip galvanizing process.

Typical coating mass: Z100–Z600 (70–425 g/m²).

Standards: ASTM A653, EN 10346, JIS G3302.

Advantages: Strong mechanical performance, economical, good formability.

Limitations: Shorter corrosion life in coastal or industrial environments.

Common applications: Residential, agricultural, and light industrial roofing.

Hengze Steel provides GI corrugated roofing sheets with uniform zinc coating and high adhesion, tested for bending and salt-spray performance to ensure long-term stability.

2.2 Aluminum-Zinc / Galvalume (GL / Al-Zn)

Composition: 55% aluminum, 43.5% zinc, 1.5% silicon.

Coating mass: AZ50–AZ185 (37–132 g/m² per side).

Advantages: Combines aluminum’s barrier protection with zinc’s sacrificial action, giving 3–6× longer life than standard galvanizing.

Reflectivity: Thermal reflectance up to 0.80; ideal for energy-efficient roofing.

Applications: Industrial, coastal, or high-humidity environments.

Hengze Steel’s Galvalume roofing coils are engineered with precise coating control and excellent surface uniformity. Each coil undergoes triple inspection for coating weight, thickness tolerance (±0.02 mm), and adhesion performance per ASTM A792.

2.3 Aluminum Corrugated Sheets

Alloys used: 3003, 3105, 5052 (H14–H32 tempers).

Key benefits:

Lightweight (approx. 2.7 g/cm³, 1/3 the density of steel).

High corrosion and UV resistance.

Suitable for curved roofs and coastal structures.

Applications: Airports, coastal resorts, canopies, lightweight structures.

Note: Requires proper insulation to avoid galvanic corrosion when paired with steel supports.

2.4 Other Metallic Options

Copper, Stainless Steel, Zinc-Titanium: Premium aesthetic materials for architectural or historical projects.

Advantages: Exceptional lifespan (>50 years), natural patina, minimal maintenance.

- Limitations: High material cost, complex installation.

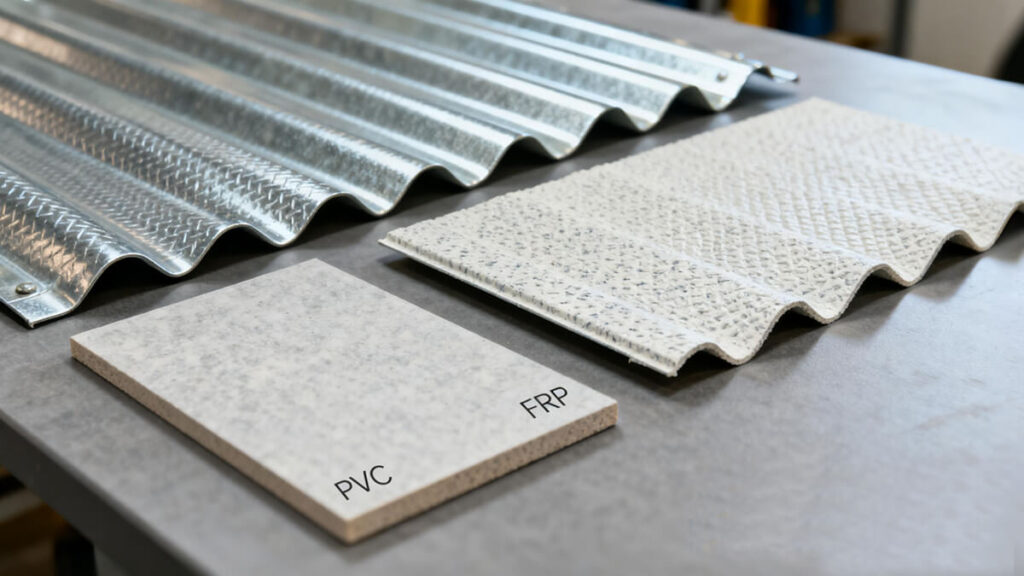

3. Non-Metal Corrugated Sheets

3.1 Fiber Cement Sheets

Composition: Portland cement, silica, cellulose fibers.

Benefits: Fire-resistant (Class A), sound-absorbing, chemically stable.

Drawbacks: Heavier (15–20 kg/m²) and brittle under impact.

3.2 Bitumen Sheets

Material: Organic fibers saturated with bitumen.

Pros: Affordable, flexible, easy to cut.

Cons: Low lifespan (typically 10–15 years), poor UV resistance.

3.3 Polycarbonate & PVC Sheets

Polycarbonate: Transparent, impact-resistant, UV-stabilized (service life ~10 years).

PVC: Lightweight and economical, but limited by thermal deformation.

4. Material Selection Criteria

When choosing a roofing sheet material, consider:

Environment: humidity, salt exposure, pollution.

Design life: 10, 20, or 30+ years.

Thickness range: typically 0.30–1.20 mm (steel), 0.50–1.50 mm (aluminum).

Load-bearing capacity: as per local wind and snow loads.

Fire code compliance and aesthetic preferences.

Budget & lifecycle cost (maintenance, repainting, replacement).

Tip: Request coating certificates and salt-spray test results from suppliers.

Hengze Steel provides full mill test reports (MTC) and coating certification for each batch, ensuring transparency and traceability.

5. Durability, Coating Systems & Service Life

| Material | Coating Type | Typical Coating Mass | Expected Lifespan* |

|---|---|---|---|

| Galvanized (GI) | Z275 | 275 g/m² | 15–25 years |

| Galvalume (GL) | AZ150 | 150 g/m² | 30–45 years |

| Aluminum | Bare / Painted | — | 25–40 years |

| Fibre Cement | None | — | 30+ years |

| Polycarbonate | UV Coated | — | 10–15 years |

*Depending on climate and maintenance frequency.

6. Weight, Structural & Installation Considerations

Weight range:

Steel: 4–10 kg/m²

Aluminum: 2–5 kg/m²

Fiber cement: 15–20 kg/m²

Thermal expansion: Allow clearance slots in fasteners for metals and plastics.

Fixings: Use EPDM-sealed self-drilling screws (for metals) or specialized clamps (for fiber cement).

Roof pitch: Minimum 7–9° for adequate water drainage.

7. Standard Specification & Procurement Checklist

Example Specification:

Material: Galvalume steel, AZ150 coating per ASTM A792.

Thickness: 0.50 mm (BMT).

Profile: Trapezoidal 32/250.

Paint System: PVDF, 25 µm top / 10 µm back.

Supplier: Hengze Steel or equivalent.

Warranty: 25 years against perforation.

8. Frequently Asked Questions

Galvalume (Al-Zn) typically lasts up to 45 years under standard exposure, outperforming traditional GI.

Aluminum offers superior corrosion resistance and lightweight benefits but at higher cost and lower stiffness.

Yes. Pre-painted systems (PPGI / PPGL) using SMP or PVDF topcoats enhance weathering resistance and color retention.

9. Conclusion: Choosing the Right Supplier

Selecting the correct corrugated roofing material ensures structural reliability, visual appeal, and long-term ROI.

When quality and consistency matter, Hengze Steel stands out as a trusted manufacturer of GI, GL, PPGI, and PPGL corrugated sheets, offering:

Precise coating control (Z/AZ weight verification)

Tight thickness tolerance (±0.02 mm)

Excellent forming and adhesion performance

Full export documentation and customized profiles

From industrial warehouses to residential villas, Hengze Steel’s corrugated roofing products deliver durability, cost-efficiency, and global standard compliance.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance