Explore Trends, Innovations, and Achievements at HengZe Steel

How to Choose Zinc Coating Thickness for Galvanized Steel Coils

- Industry News

- December 30, 2025

- 6:41 am

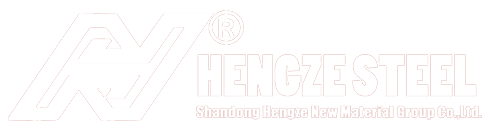

Selecting the appropriate zinc coating thickness is a fundamental step when specifying galvanized steel coils for construction, manufacturing, and infrastructure projects. Zinc coating thickness directly affects corrosion resistance, expected service life, fabrication performance, and long-term cost efficiency.

An under-specified zinc layer may result in premature corrosion, especially in outdoor or aggressive environments. Conversely, excessively heavy zinc coatings can increase material costs and may influence forming or welding performance. Understanding how to align zinc coating thickness with real application conditions is essential for optimizing both performance and total lifecycle cost.

As an experienced galvanized steel coil supplier, Hengze Steel Group works closely with engineers, contractors, and buyers to ensure zinc coating specifications match actual service environments and processing requirements.

Table of Contents

- 1️⃣ Understanding Galvanized Steel Coil and Zinc Coating Basics1️⃣ Understanding Galvanized Steel Coil and Zinc Coating Basics

- 2️⃣ Common Standards & Zinc Coating Thickness Classifications2️⃣ Common Standards & Zinc Coating Thickness Classifications

- 3️⃣ Factors That Influence Zinc Coating Thickness Selection3️⃣ Factors That Influence Zinc Coating Thickness Selection

- 4️⃣ Matching Zinc Coating Thickness to Specific Applications4️⃣ Matching Zinc Coating Thickness to Specific Applications

- 5️⃣ Testing and Quality Assurance of Zinc Coating Thickness5️⃣ Testing and Quality Assurance of Zinc Coating Thickness

- 6️⃣ Cost, Performance, and Lifecycle Considerations6️⃣ Cost, Performance, and Lifecycle Considerations

- 7️⃣ Practical Tips for Procurement and Specification7️⃣ Practical Tips for Procurement and Specification

- 8️⃣ Conclusion8️⃣ Conclusion

1️⃣ Understanding Galvanized Steel Coil and Zinc Coating Basics

🔹 What Is a Galvanized Steel Coil?s

A galvanized steel coil is produced by coating a steel strip with zinc to protect the base metal from corrosion. The most common production method is continuous hot-dip galvanizing, in which steel passes through molten zinc to form a durable metallurgical bond.

Electro-galvanized steel coils are also used where precise coating control and smooth surface quality are required, although their zinc coating thickness is generally lower than that of hot-dip galvanized products.

🔹 How Zinc Coating Protects Steel

Zinc protects steel through a combination of barrier protection and sacrificial action. The zinc layer prevents moisture and oxygen from reaching the steel surface, while also acting as a sacrificial anode that corrodes preferentially to steel.

This mechanism explains why galvanized steel coils with higher zinc coating thickness typically deliver superior corrosion resistance and extended service life, particularly in coastal, industrial, and high-humidity environments.

2️⃣ Common Standards & Zinc Coating Thickness Classifications

🔹 ASTM and EN Zinc Coating Standards

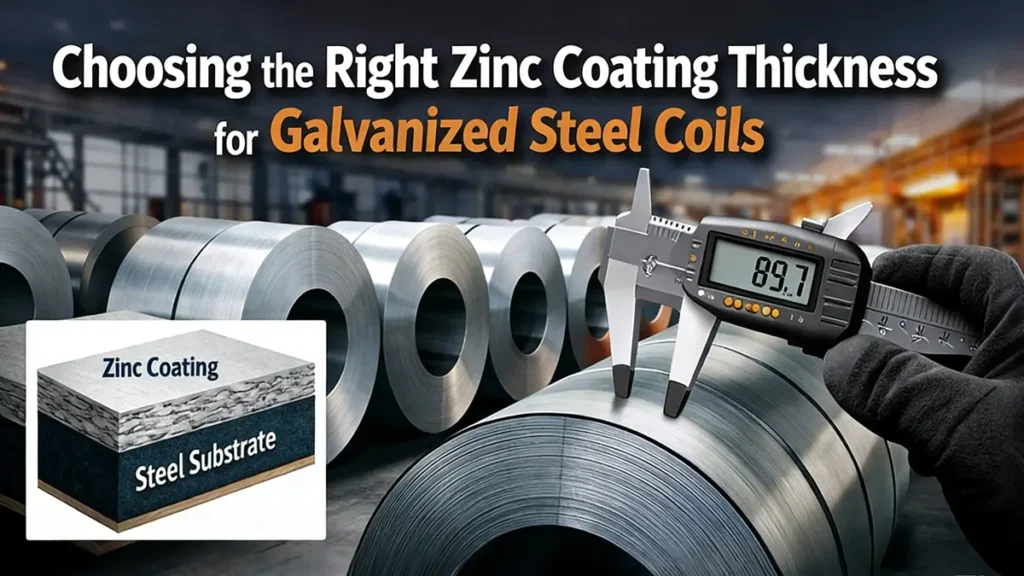

Zinc coating thickness for galvanized steel coils is defined by internationally recognized standards to ensure consistent performance:

ASTM A653 / A653M specifies coating weights such as G30, G60, and G90, commonly referenced in North American markets.

EN ISO 10346 defines zinc coatings using metric Z values such as Z120, Z180, and Z275, widely used in Europe and global trade.

Accurately referencing these standards in specifications and purchase orders helps prevent mismatches between expected and delivered corrosion performance.

🔹 Understanding Z Values and G Grades

Z values (such as Z120 or Z275) indicate the total zinc coating weight applied to both sides of the steel strip, measured in grams per square meter. For example, Z275 galvanized steel coils are widely specified for outdoor construction and industrial applications due to their enhanced corrosion resistance.

G steel grades (such as G60 or G90) express coating weight under ASTM standards. A G90 galvanized steel coil offers significantly greater corrosion protection than lighter grades like G30 and is often selected for demanding environments.

Although expressed differently, both systems serve the same function: defining zinc coating thickness and expected durability.

3️⃣ Factors That Influence Zinc Coating Thickness Selection

Choosing the correct zinc coating thickness requires a comprehensive evaluation of application conditions:

Environmental exposure: Coastal, industrial, or high-pollution environments accelerate corrosion and generally require heavier zinc coatings.

Fabrication and forming processes: Punching, bending, stamping, and deep drawing can locally reduce coating thickness, making higher initial zinc weights advisable.

Service life expectations: Long-design-life projects benefit from thicker coatings that minimize maintenance and replacement.

Base steel thickness and grade: Heavier substrates typically support thicker zinc coatings more effectively during hot-dip galvanizing.

Suppliers such as Hengze Steel often assist buyers in balancing these factors to avoid both under- and over-specification.

4️⃣ Matching Zinc Coating Thickness to Specific Applications

🔹 Indoor and Low-Corrosion Environments

For indoor applications such as interior panels, cable trays, and HVAC systems—where moisture and corrosive exposure are minimal—lighter zinc coatings like Z100 or Z120 galvanized steel coils are usually sufficient and cost-efficient.

🔹 Urban and Industrial Applications

In urban or industrial environments, galvanized steel is exposed to pollutants, condensation, and temperature fluctuations. Medium-weight coatings such as Z275 or ASTM A653 G90 galvanized steel coils are commonly specified to ensure stable corrosion resistance, often combined with paint or powder coating systems.

🔹 Coastal and Harsh Environments

Coastal environments present severe corrosion challenges due to salt-laden air. In these conditions, galvanized steel coils with zinc coating thickness above Z275 are strongly recommended, frequently used as part of a duplex protection system to maximize service life.

🔹 Forming, Stamping, and Fabrication Requirements

For applications involving extensive forming or stamping, zinc coating thickness may be reduced at high-stress deformation areas. Selecting a slightly heavier coating helps ensure adequate corrosion protection remains after fabrication.

5️⃣ Testing and Quality Assurance of Zinc Coating Thickness

Reliable quality control ensures zinc coating thickness meets specification:

Magnetic thickness gauges provide fast, non-destructive measurements.

Weight-based methods calculate coating mass, with approximately 1 μm of zinc equivalent to 7.14 g/m².

Cross-sectional microscopy offers precise laboratory verification for critical applications.

Reputable galvanized steel coil manufacturers and exporters supply mill test certificates and inspection data to support traceability.

6️⃣ Cost, Performance, and Lifecycle Considerations

Zinc coating thickness should always be evaluated from a lifecycle cost perspective:

Thicker coatings increase initial cost but significantly reduce corrosion-related maintenance.

Thinner coatings may be suitable for controlled environments or when combined with secondary protective systems.

Optimized zinc thickness selection helps minimize total cost of ownership while ensuring reliable performance.

7️⃣ Practical Tips for Procurement and Specification

Specify exact coating standards such as Z275 or ASTM A653 G90 rather than generic descriptions.

Clearly communicate environmental exposure and fabrication requirements during procurement.

Request mill test certificates and zinc coating thickness inspection reports.

Consider duplex systems for projects exposed to aggressive corrosion conditions.

8️⃣ Conclusion

Choosing the right zinc coating thickness for your galvanized steel coil project is a critical technical and economic decision. By understanding coating standards, environmental conditions, fabrication demands, and lifecycle expectations, buyers can specify galvanized steel coils that deliver consistent corrosion resistance and long-term value.

With professional technical support and stable supply capabilities, Hengze Steel Group helps customers select galvanized steel coil solutions that balance durability, performance, and cost across a wide range of applications.

FAQs

What does Z120 mean on a galvanized steel coil?

Z120 indicates a total zinc coating weight of 120 g/m² applied to both sides of the steel strip.

Is a thicker zinc coating always better?

Not necessarily. Thicker coatings improve corrosion resistance but may be unnecessary for indoor or low-corrosion environments. Zinc coating thickness should match actual service conditions.

Can zinc coating thickness be measured after production?

Yes. Magnetic gauges, weight-based calculations, and microscopic analysis are commonly used to verify zinc coating thickness.

Trending News

What to Expect When You Contact Us

Fast Response – Replies within 12 hours

Tailored Solutions – Based on your needs and industry

Full Support – From products to technical and market guidance